Company News

Moldeo por inyección problemas comunes de cavitación del producto

2022-04-25The so-called cavitation means that the material in the injection mold starts to solidify from the surface, and the entire volume in the mold is relatively insufficient, so a hole in a vacuum state is formed. It usually appears at the thickness of the product and the nozzle material.

Transparent products have cavitation problems, opaque products have no obstacles to cavitation, and they should not be seen inside the product. Cavitation caused by moisture and volatiles generally spreads to all parts of the product,

The shape of cavitation is generally relatively small.

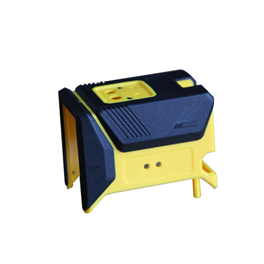

Injection mold opening

one. What are the causes of cavitation in injection molded products?

1. Insufficient pressure in the injection mold

2. There is moisture and volatility in the material

3. Excessive and uneven thickness of injection molded products

Two: What are the solutions to cavitation of injection molding products?

1. Increase the injection pressure of injection molding and prolong the holding time. Due to the moisture and volatility of the plastic, the plastic material must be fully dried, and the temperature of the heating barrel can be reduced.

2. The injection gate and gate can be appropriately enlarged.

3. Eliminate excessive thickness of the product.

Three: due to differences in materials

1. Cavitation and other problems are prone to occur when crystalline materials and products are thick.

Four: matters needing attention

1. It is better to let the injection-molded product cool slowly after taking it out.

Inglés

Inglés España

España Alemán

Alemán