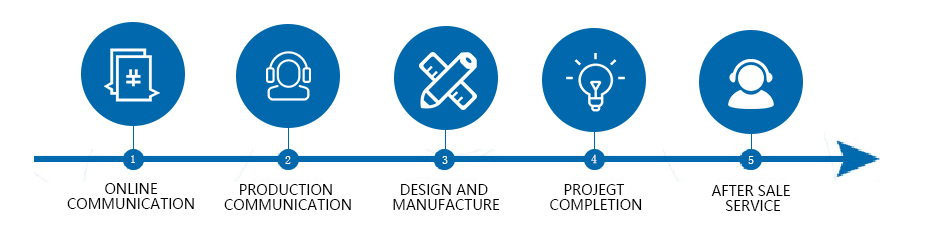

Our Service

1,Flow Chart

Inquiry stage we need 3D and 2D part drawing.requested mold standards, mold cavities,and part material to quote our best price.

New prgject starts stage-PO and latest drawing(2D and 3D) from customer.Then our engineer provide DFM based on the latest drawing.And we send our mold drawing to customer to double review after short communication on DFM with customer.

During mold making-after customer release the mold drawing, we start to make mold. during mold making, we provide weekly moldprocessing reprt, includling mold processing pictures to customer each week so that customer can also monitor the mold processin ill themold was finished.

Project finished stage.

1.For exported mold, we will make sure the mold no problem for production after customer confrmed the mold delivery before we deliver themold.

2.For regular production mold in our factory,we will maintain the mold after production.

3.For plastic parts production, cur engineer will check the part dimension based on confrmation sample and drawing before ma55

production. We pack the parts based on customers' requirements. f customer does not have any requirements, we will andle the packingbased on the quality of the parts.

After sales stage一 if there is any issue for parts or molds from customer, we will prove the issue with customer at the frt time. lfit is curfault, we will take responsibility. lf it is not our fault, we will also spport customer to solve the problem.

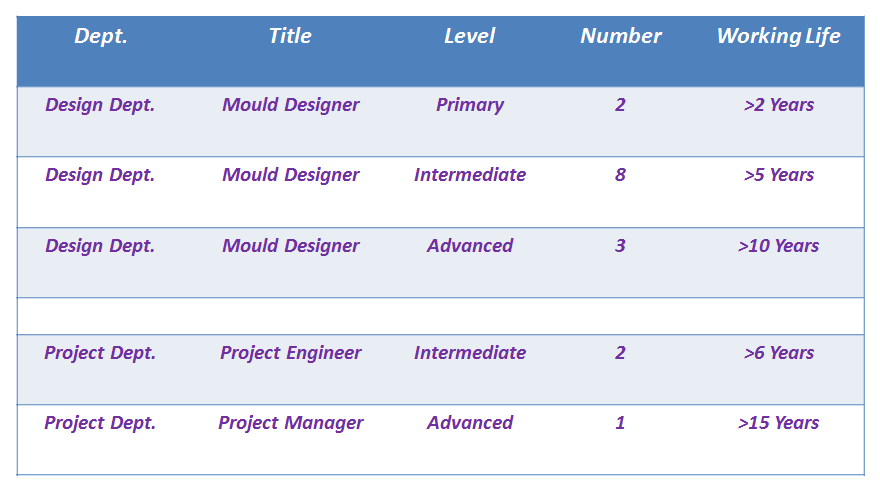

2,Engineering Ability

Our company has a complete set of personnel for design and project control. At present, there are 13designers and 3 project control personnel.The specific configuration is shown in the table belowrol. Atpresent, there are 13 designers and 3 project control personnel.The specific configuration is shown inthe table below

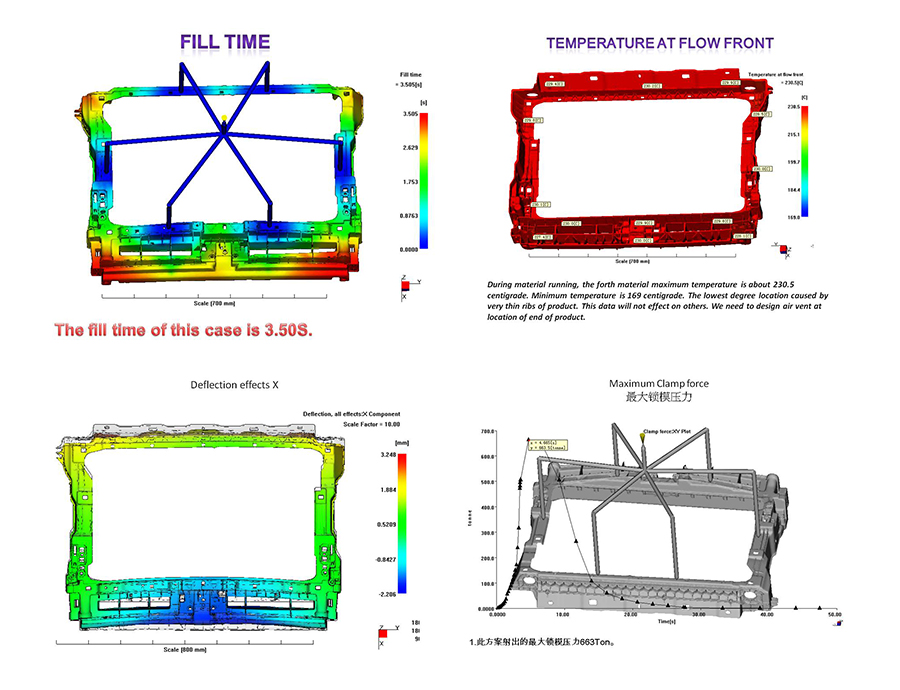

3,Mold Flow Analysis

In many cases, there is a botleneck in mold design and processing, that is,mold design and processing have been completed, but there are many

problems in production. In order to make mold design more rational, ourcompany usually helps customers carry out mold flow analysis, which canreduce the blindness in mold design and processing.The following is thepicture of our model flow analysis.

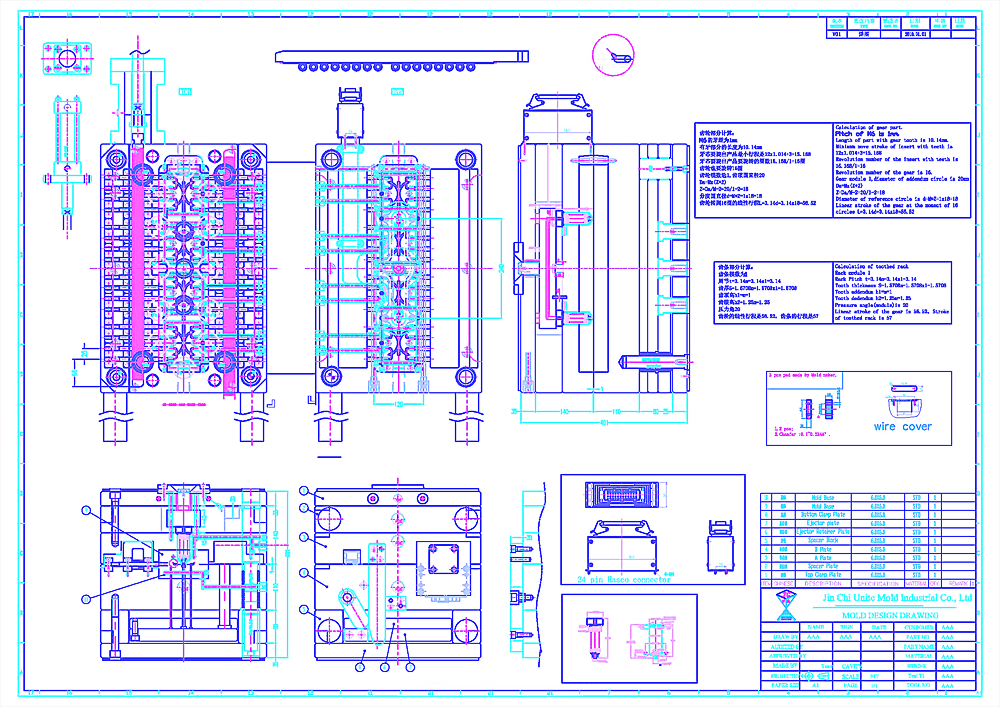

3,Mould Design--2D

In the past, at the beginning of a project, we usually design 2D moldsaccording to customer requirements. The following picture is ah example ofour 2D engineering drawings of a mold.

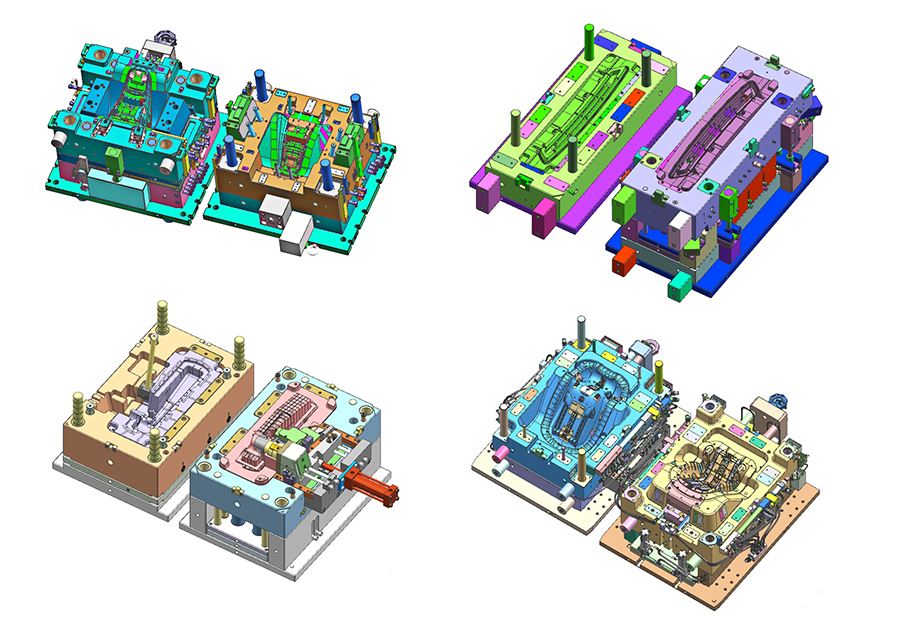

4,Mould Design--3D

With 3 d software function of increasingly powerful, we can see any of thecomponent directly on full 3D model. This is a great convenience forcustomer to audit the model. and also convenient for us to communicatewith customer directly. Below is the picture of the 3d Model from us.

English

English Spain

Spain Deutsch

Deutsch