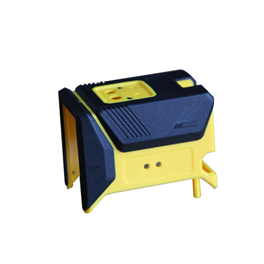

TP-Link cover

Brief Introduction: TP-LINK cover molded by injection mold

Part Material: PC/ABS

Part Size: 270x185x74mm

Dimensional Tolerance: Overall dimension ≤ ±0.1mm local size ≤ ±0.02mm

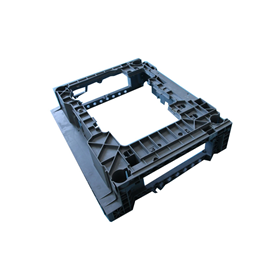

Technical Issue:very high appearance requirements, no weld lines no injection marks no flashes. High precision size requirements. A lot of small kiss off holes in the mould.

Send Inquiry

Our Capability:

CNC machining

High speed CNC machining

EDM machining

Charmill EDM machining

Sodick LS-WEDM machining

Wire Cutting EDM machining

MT Texture/VDI3400 Texture/Yixin Texture

CMM(Coordinates Measuring Machine) measure

OMM(Optical Measuring Machine) measure

Robotic manipulator pick out products

Adjust the product color according to the RAL or Pantone color card

This is a TP-LINK cover sample produced by injection mould that our company helps customers to process. Very strict appearance requirements. There are a lot of kiss off structures on the mould which makes fitting mould very difficult. In order to ensure the mould life, Core steel adopts hardening and surface nitriding treatment. Besides, because of a large number of holes, welding lines are easy to appear during injection molding, and it is very difficult to adjust the injection machine parameter. However, through the efforts of all employees of our company, all the problems have been overcome one by one, and the mold production is smooth. Once the sample was sent to the customer, it passed the performance testing very quickly and won great praise from the customer.

Please feel free to give your inquiry in the form below. We will reply you within 24 hours.

English

English Spain

Spain Deutsch

Deutsch